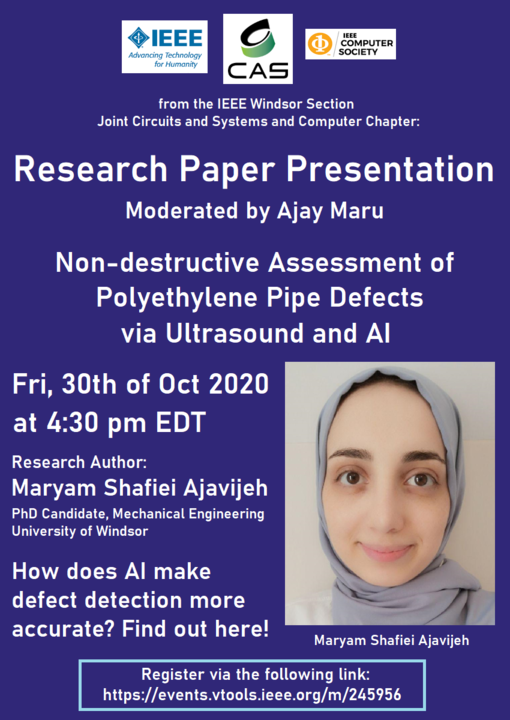

Research Presentation Moderated by Ajay Maru - Non-destructive Assessment of Polyethylene Pipe Defects via Ultrasonic and AI

#research

#paper

#deep

#dive

#presentation

#ultrasonic

#AI

#artificial

#intelligence

#destructive

#non-destructive

#testing

#polyethylene

#pipe

#defects

This will be a technical deep dive of a single piece of research work, complete with questions about the existing methods, proposed method, materials/equipment used, procedure, analysis method, and conclusion. Think of this as practice for a proposal/progress seminar or defense presentation in front of committee members in preparation for graduating from a PhD or Master's program or completing a Capstone Project.

Research Topic: Based on IEEE IUS 2020 Presentation: Ultrasound Flaw Detection of Medium-Density Polyethylene Fused Joints Using Chord Transducers and Implementation of Artificial Intelligence.

To make sure that pipes and pipe joints are built within a specification, and that they do not have defects, an instrument sends a signal to be bounced from the piping material to be analyzed. That same instrument thus receives that signal and generates a defect signature, a picture that tells the person looking for a defect as to whether or not there is a defect.

This method is not accurate, so the instrument in use in this work is an ultrasonic transducer, and the analysis has been augmented by artificial intelligence.

Artificial intelligence, however, is known mainly for analysis of the raw data after it has been collected, and it is a game of statistics, so its accuracy has to be tested as well.

How does artificial intelligence make detection of defects in pipe joints more accurate? Find out!

(The presentation will be streamed live via Microsoft Teams.)

(Please note: The presentation will be recorded. By viewing the event, you agree to have your video and audio recorded if you choose to contribute to the discussion, including, but not limited to, the question-and-answer section.)

Date and Time

Location

Hosts

Registration

-

Add Event to Calendar

Add Event to Calendar

- Contact Event Host

-

Moderator: Ajay Maru, Secretary, IEEE Windsor Section Joint Circuits and Systems (CAS04) and Computer (C16) Chapter

Email: maru@uwindsor.ca

Speakers

Maryam Shafiei Ajavijeh, Mechanical Engineering PhD Candidate and Secretary, IEEE Women in Engineering Affinity Group, IEEE Windsor Section of Institute for Diagnostic Imaging and Research, University of Windsor

Maryam Shafiei Ajavijeh, Mechanical Engineering PhD Candidate and Secretary, IEEE Women in Engineering Affinity Group, IEEE Windsor Section of Institute for Diagnostic Imaging and Research, University of Windsor

Biography:

Maryam Shafiei Ajavijeh specializes in detection of defects in polymer and metal structures. She has designed the experiments and testing procedures themselves, run the detection tools, and analyzed the results using artificial intelligence and machine learning to classify the structure flaws that have been detected. She has done both destructive testing and non-destructive testing. She has faciliatated entire project teams and even instructed students in courses related to this work.

Research Experience:

PhD Project: Application of ultrasound technology for polyethylene (PE) butt-fusion and electro-fusion pipes joints with non-destructive evaluation by applying an autoencoder machine learning model. Implementation of the autoencoder AI model for defect recognition in pipe joints has been done. A-scans of good joints have been collected to form a training dataset and various defective joints were introduced as outlier signals. Model accuracy has been validated by high speed tensile test and bending destructive testing.

M.Sc. Project: Experimental and numerical study on damage detection and localization on composite materials by utilizing ultrasonic guided waves for Structural Health Monitoring (SHM). Coding SAFE method “semi-analytical finite element” in MATLAB for extracting dispersion curves.

B.Sc. Project: Split sleeve leak repair clamp stress analysis using the finite element method and experimental investigation of NBR and Viton polymers to determine yield strain under certain pressure.

Research project in University of Windsor's Institute for Diagnostic Imaging Research (IDIR): Optimization of a cooling system design for an ultrasound transducer in a spotweld automotive robot. Numerical analysis has been done in ABAQUS to optimize the transducer design.

Presented Research Work:

Presented poster, IEEE IUS 2020, Ultrasound Flaw Detection of Medium-Density Polyethylene Fused Joints Using Chord Transducers and Implementation of Artificial Intelligence

Accepted conference paper, World Conference on Non-Destructive Testing: Ultrasound inspection of butt fusion joints of Medium-density polyethylene pipes.

Accepted conference paper, SHM-NDT 2020 Structural Health Monitoring & Non-Destructive Testing: inspection of butt fusion joints of Medium-density polyethylene pipes using pulse-echo Ultrasound.

Accepted conference paper, Canadian Institute For Non-Destructive Evaluation (CINDE): A-scan ultrasound pitch-catch method using chord transducer for inspecting of polyethylene butt fusion joints defects.

Accepted Manuscript, 12th European Conference on Non-Destructive Testing (12th ECNDT) Conference: Numerical and Experimental delamination sizing in an 8 Layer WGF/epoxy composite plate using ultrasonic Lamb waves.

Accepted Manuscript, 7th ISAV2017 international conference on acoustic and vibration: Experimental study on delamination detection in a WGF/epoxy composite plate using ultrasonic guided waves by introducing a novel model ARR.

Research assistance at the University of Windsor: Serving as an alternative instructor in lectures, preparing and delivering tutorial exercises, assisting in setup and proctoring the exams for courses:

• Numerical analysis for engineering (Winter 2019)

• Engineering economics (Summer 2019)

• Engineering measurement (Fall 2019)

• Numerical analysis for engineering (Winter 2020)

• Product, Mfg Proc & Bus Integ (Summer 2020) • Dynamic (Fall 2020)