SusTech Talk: Enabling Distributed Ammonia Production with Microwaves

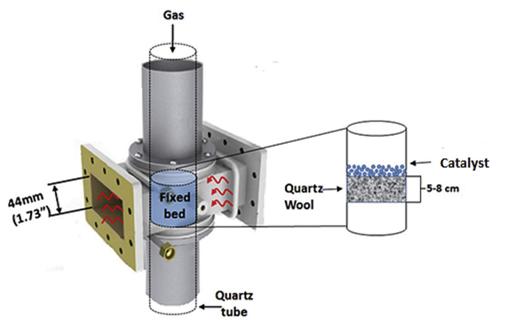

The Haber-Bosch process has remained the industry standard for ammonia synthesis for the last 100 years and is considered one of the greatest innovations of the 20th century. This process today produces about 150 million tons of ammonia per year and utilizes around 1% of the total energy supply of the world. The HB process has been fine-tuned and has gained great efficiencies at large scale over this time; however, the large-scale processes is now a large contributor in carbon emissions. A significant effort has been placed recently to both lower processing conditions and modularize the ammonia process so that it can be better paired with renewable energy to make the process green. A partnership between WVU, NETL, and Malachite technologies has developed a process using microwaves to lower the processing temperature and pressure for ammonia synthesis. This process utilizes the microwaves to selectively heat the active sites of the catalyst which lowers the bulk temperature of the reaction and has shown the highest ammonia production rates at low pressure conditions than competing methods such as electrolytic and plasma. Microwaves provide a unique direct heating of the catalyst that provides quick ramps and load following ability for pairing with renewable energy. The group has worked through significant challenges such as catalyst development and scale-up for the microwave reactors and will be discussed in this talk. The process has been demonstrated at 1kg/day at 300°C and 300psi and will enable distributed ammonia production for local farm communities and energy storage for wind turbines.

Date and Time

Location

Hosts

Registration

-

Add Event to Calendar

Add Event to Calendar

Loading virtual attendance info...

Speakers

Christina of NETL

Christina of NETL

ENABLING DISTRIBUTED AMMONIA PRODUCTION WITH MICROWAVES

The Haber-Bosch process has remained the industry standard for ammonia synthesis for the last 100 years and is considered one of the greatest innovations of the 20th century. This process today produces about 150 million tons of ammonia per year and utilizes around 1% of the total energy supply of the world. The HB process has been fine-tuned and has gained great efficiencies at large scale over this time; however, the large-scale processes is now a large contributor in carbon emissions. A significant effort has been placed recently to both lower processing conditions and modularize the ammonia process so that it can be better paired with renewable energy to make the process green. A partnership between WVU, NETL, and Malachite technologies has developed a process using microwaves to lower the processing temperature and pressure for ammonia synthesis. This process utilizes the microwaves to selectively heat the active sites of the catalyst which lowers the bulk temperature of the reaction and has shown the highest ammonia production rates at low pressure conditions than competing methods such as electrolytic and plasma. Microwaves provide a unique direct heating of the catalyst that provides quick ramps and load following ability for pairing with renewable energy. The group has worked through significant challenges such as catalyst development and scale-up for the microwave reactors and will be discussed in this talk. The process has been demonstrated at 1kg/day at 300°C and 300psi and will enable distributed ammonia production for local farm communities and energy storage for wind turbines.

Biography:

Christina Wildfire has served as a researcher at NETL since 2016 on the Reaction Engineering Team. Currently, she is leading research to decarbonize the chemical industry using microwaves to electrify high emitting, energy intensive processes. Some projects include low pressure ammonia synthesis and CO2 utilization using a microwave reactor. She also investigates the interactions and mechanisms of materials in a microwave field to aid in materials synthesis/processing and scale-up of microwave driven processes. Dr. Wildfire’s research interests include: material synthesis, catalysis, microwave reactions, and scale-up. Dr. Wildfire received her BS and MS in Mechanical Engineering from Mercer University in Macon, GA and her PhD in Material Science from West Virginia University in Morgantown, WV.