Evaluation of 3D Printed Soft Robots in Radiation Environments and Comparison With Molded Counterparts

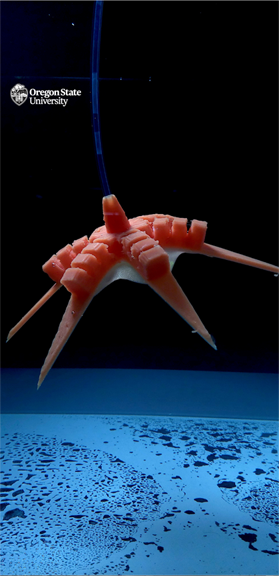

Robots have an important role during inspection, clean-up, and sample collection in unstructured radiation environments inaccessible to humans. The advantages of soft robots, such as body morphing, high compliance, and energy absorption during impact, make them suitable for operating under extreme conditions. Despite their promise, the usefulness of soft robots under a radiation environment has yet to be assessed. In this work, we evaluate the effectiveness of soft robots fabricated from polydimethylsiloxane (PDMS), a common fabrication material, under radiation for the first time. We investigated gamma-induced mechanical damage in the PDMS materials’ mechanical properties, including elongation, tensile strength, and stiffness. We selected three radiation environments from the nuclear industry to represent a wide range of radiation and then submerged a 3D printed hexapus robot into a radiation environment to estimate its operation time. Finally, to test the reliability of the 3D printed soft robots, we compared their performances with molded counterparts. To analyze performance results in detail, we also investigated dimensional errors and the effects of fabrication methods, nozzle size, and print direction on the stiffness of PDMS material. Results of this study show that with increasing exposure to gamma irradiation, the mechanical properties of PDMS decrease in functionality but are minimally impacted up to 20 kGy gamma radiation. Considering the fractional changes to the PDMS mechanical properties, it is safe to assume that soft robots could operate for 12 h in two of the three proposed radiation environments. We also verified that the 3D printed soft robots can perform better than or equal to their molded counterparts while being more reliable.

Date and Time

Location

Hosts

Registration

-

Add Event to Calendar

Add Event to Calendar

Loading virtual attendance info...